Do you know what can quickly enhance the quality of packaging? It’s packaging technology. These technologies help you better express your brand philosophy, improve the user experience, and make ordinary packaging more three-dimensional and sophisticated. Next, we will analyze four technologies in detail.

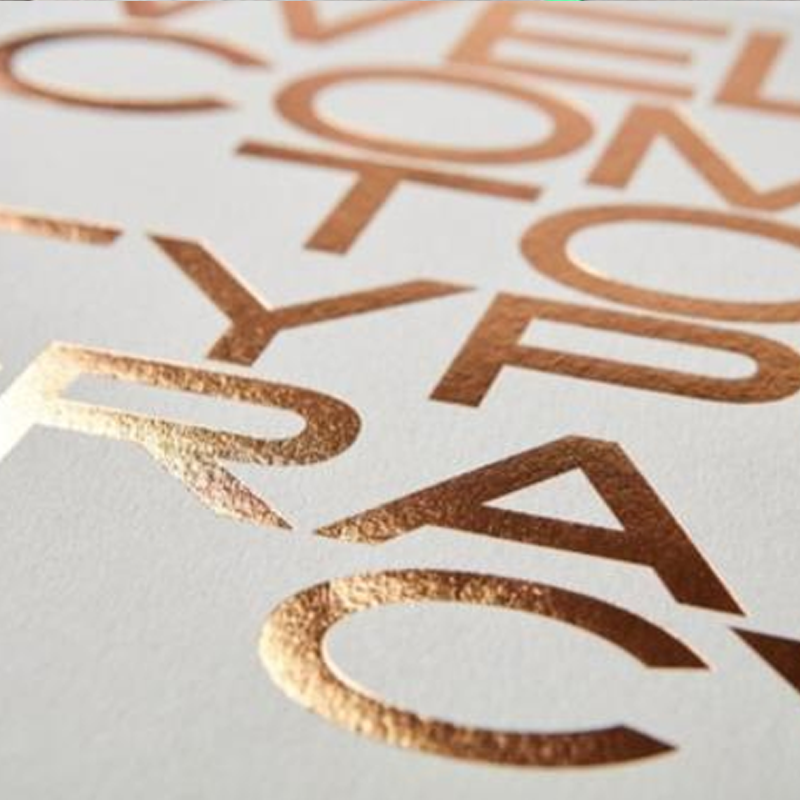

I. Hot stamping process

Process Description:

Also known as hot stamping, it uses pressure and temperature to heat-press metal foil onto packaging, which can highlight brand logos and patterns, and strengthen consumers’ impression of the brand.

Features :

- High gloss : It can create highly reflective and eye-catching decorative elements that convey a sense of luxury.

- Various colors : There are many types of hot stamping foil materials, including gold, silver, laser, black, red, etc., which can be adapted to various brand styles.

- Applications : Premium gift boxes, card holders, paper bags, greeting cards, business cards, etc.

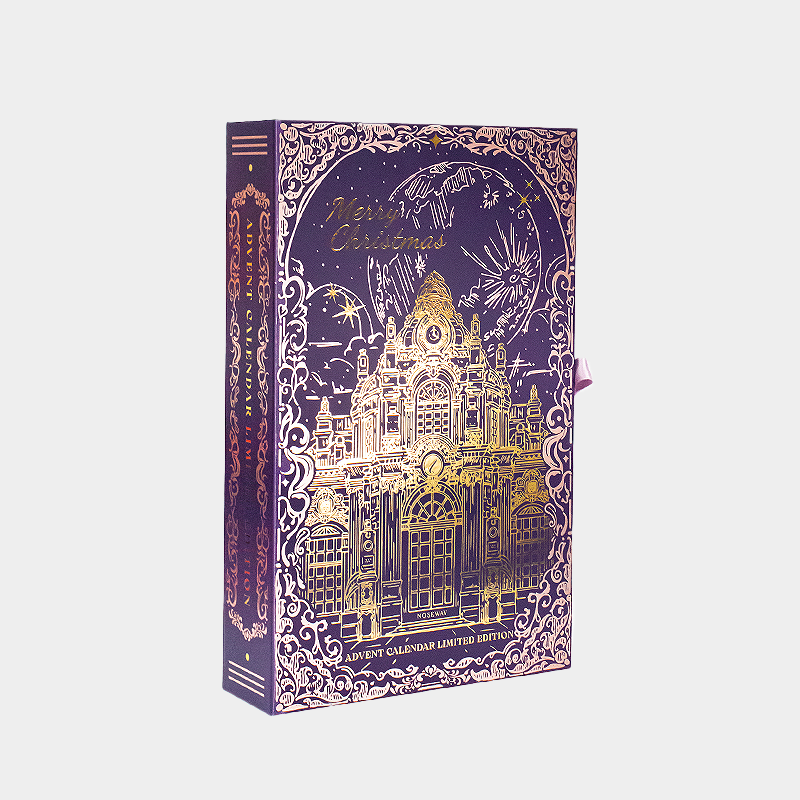

JS Packaging Case Study:

- Christmas Gold-Stamped Book-Shaped Gift Box : The all-over gold foil stamping creates a festive atmosphere and enhances the packaging’s sophistication, perfectly embodying the brand’s luxurious style.

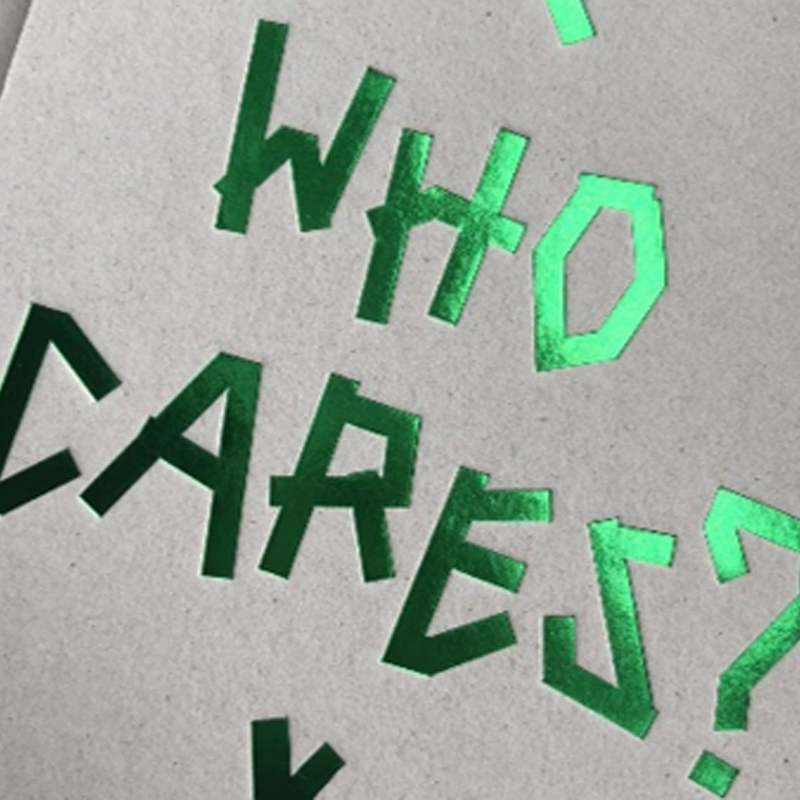

- Green and gold foil logo on the gift bag : The green and gold foil logo makes this gift box stand out on the shelf, attracting customers’ attention and strengthening their impression of the brand.

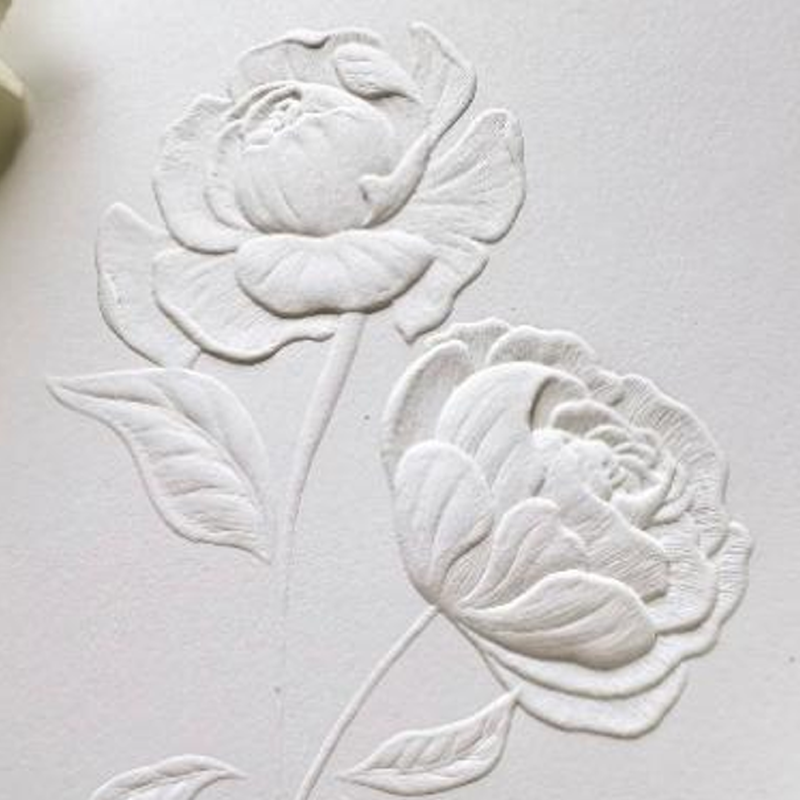

II. Embossing process

Process Description:

Also known as embossing, this technique uses a mold under pressure to create raised, three-dimensional patterns or text on the surface of paper packaging. No additional ink is needed; the decorative effect is achieved solely through changes in the material itself, giving the packaging a more tactile and layered feel .

Features :

- Strong sense of three-dimensionality : Raised patterns or text can be directly touched and perceived, breaking the monotony of flat packaging, highlighting the visual and tactile effects of key information, and enhancing user memory.

- High-quality feel : It does not rely on color, but only on the undulations of the paper to show a simple and exquisite style, which is suitable for brands that pursue environmental protection, understated luxury and pay attention to the quality of details.

Applications : Eco-friendly gift boxes, cosmetic packaging boxes, paper bags, hang tags, etc.

JS Packaging Case Study:

- Embossed Top and Bottom Lid Gift Box : This top and bottom lid gift box uses a lot of embossing technology to make the originally monotonous gift box three-dimensional, reflecting the brand’s environmental protection concept while presenting a beautiful and textured packaging.

III. Embossing Process: Creating a Three-Dimensional Texture

It is a process that uses a mold with a specific texture to press the texture onto the surface of the packaging material under pressure. It can form continuous and regular textures on various materials such as paper or leather, giving the packaging surface a rich texture.

Core features

- Enhance tactile interaction : It can replicate various natural textures such as wood grain, fabric texture, and terraced fields, thereby improving the quality of packaging.

- The design is widely applicable : it can be used to present various elements such as logos, patterns (such as floral patterns, geometric patterns), or text.

Applications : Gift packaging, eco-friendly packaging, gift bags, packaging materials, etc.

IV. UV Coating Process: Combining gloss, protection, and contrast effects Process Principle

UV coating involves first applying a liquid, transparent coating to the packaging surface, then instantly curing it by irradiation with ultraviolet light. This process offers two types: partial UV coating and full UV coating, producing various effects such as glossy, matte, or frosted finishes.

Core features

- Fast curing speed : No need to wait for the coating to dry, significantly shortening production time.

- Excellent protective performance : It can effectively resist scratches, prevent moisture and fading, and extend the service life of the packaging.

- Applications : Cosmetic packaging boxes, food gift boxes, electronic product gift boxes, gift bags, etc.

JS Packaging Case Study:

- UV-coated triangular gift box : This gift box uses partial UV coating , and the pattern changes under light, giving it a high-quality feel and enhancing the brand’s image.

Summary: Choosing the right process for your brand

No matter your brand, these techniques allow your packaging to tell your brand story and become an effective marketing tool. Contact JS Packaging for customized packaging solutions and pricing. We also offer sampling services so you can see the effects of the techniques on your packaging more clearly.