A Comprehensive Guide on How to Make Custom Paper Boxes

Custom paper boxes are versatile packaging solutions that cater to various industries, from cosmetics to food and retail. Understanding how to make paper boxes allows manufacturers and businesses to create unique packaging that reflects their brand identity and meets their specific requirements. In this comprehensive guide, we will delve into the step-by-step process of making custom paper boxes, from design to production, providing valuable insights and tips for beginners and seasoned professionals alike.

Understanding the Basics of Paper Box Design

- Definition of custom paper boxes and their importance in branding and product packaging.

- Factors to consider when designing custom paper boxes, including size, shape, material, and printing options.

- Introduction to design software and tools for creating custom box templates and prototypes.

Choosing the Right Materials for Paper Box Production

- Overview of different types of paperboard and cardboard materials commonly used in paper box manufacturing.

- Factors to consider when selecting materials, such as thickness, durability, and sustainability.

- Tips for sourcing high-quality materials and establishing relationships with reliable suppliers.

Preparing for Paper Box Production

- Step-by-step guide to creating a paper box template using design software or manual measurements.

- Understanding dieline templates and how they guide the production process.

- Tips for optimizing the design for efficient manufacturing and cost-effective production.

Printing and Customization Techniques for Paper Boxes

- Overview of printing options for custom paper boxes, including offset printing, digital printing, and special finishes.

- Introduction to customization techniques such as embossing, debossing, and foil stamping.

- Tips for selecting the right printing method and customization options based on budget and design requirements.

Assembling and Finishing Custom Paper Boxes

- Step-by-step instructions for cutting, scoring, and folding paper box templates for assembly.

- Techniques for gluing, taping, or interlocking box components to ensure structural integrity.

- Tips for adding finishing touches, such as inserts, labels, and ribbons, to enhance the presentation of custom paper boxes.

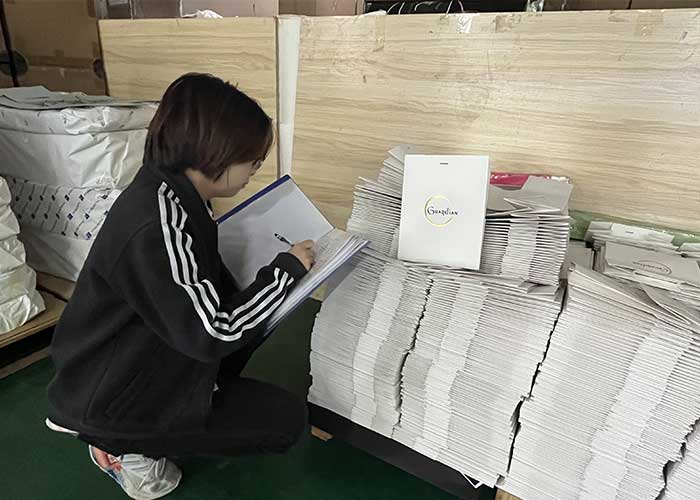

Quality Control and Packaging for Custom Paper Boxes

- Importance of quality control measures in ensuring the consistency and durability of custom paper boxes.

- Tips for conducting quality inspections at various stages of the production process.

- Best practices for packaging custom paper boxes to protect them during shipping and storage.

Marketing and Selling Custom Paper Boxes

- Strategies for promoting custom paper boxes to a target audience, including branding, packaging design, and online marketing.

- Tips for pricing custom paper boxes competitively and maximizing profit margins.

- Insights into industry trends and innovations in custom paper box manufacturing.

Mastering the art of making custom paper boxes requires a combination of creativity, technical skill, and attention to detail. By following the step-by-step process outlined in this guide, manufacturers and businesses can create unique and impactful packaging solutions that set their products apart in the market. Whether you are a novice looking to learn the basics or a seasoned professional seeking to enhance your skills, this comprehensive guide serves as a valuable resource for anyone interested in the art of custom paper box manufacturing.