Hi, brands and merchants ! 🌍

JS Packaging, a packaging brand with over 20 years of experience in the custom paper bag industry and serving more than 2,000 clients worldwide , will share some insider secrets of paper bag customization today . We will break down 6 key factors for custom paper bags to help you avoid the pitfalls of packaging customization factories.

I. Dimensions

Paper bag sizes have specific, scenario-specific requirements; you need to focus on confirming whether the factory has the following capabilities:

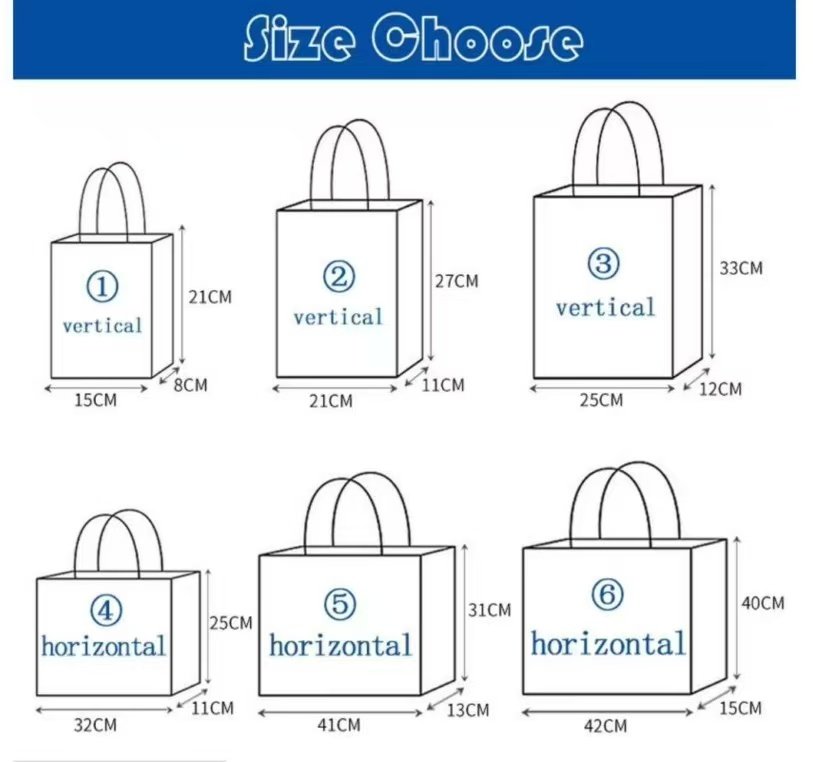

- Standard Sizes : The following are commonly used sizes for paper bags. You can choose the appropriate size according to the size of your product.

- Non-standard sizes : If special sizes are required, such as extra-long tote bags or extra-flat paper bags, can the factory quickly provide structural design solutions and verify the rationality of the dimensions through sampling?

- Size and load-bearing capacity : Can you recommend the optimal length, width, and height ratio of the paper bag based on the weight of your product to avoid problems such as large size but insufficient load-bearing capacity, or excessive packaging space?

II. Material

Many countries have extremely high standards for packaging environmental protection and safety. So how do you choose a reliable packaging factory? Consider the following three points:

- Fully Certified Environmentally Friendly : Prioritize factories that can provide FSC forest certification, BSCI, SGS , ISO 9001 , and CQM reports to avoid goods being detained by customs due to non-compliance. JS Packaging possesses these qualifications.

- High material compatibility : Confirm with the factory whether they have the material type and thickness you need . For example, 250g kraft paper is suitable for supermarket shopping bags and offers high cost performance; 250-300g white cardboard is suitable for high-end gift bags and offers rich printing colors; coated paper is waterproof and wear-resistant and suitable for various industries.

- Material performance testing : Select factories that provide sample services and burst strength and load-bearing capacity tests to ensure that no easily broken defective products will occur during mass production.

III. Process

The craftsmanship of paper bags can be confirmed through sampling or by visiting the factory in person. If you cannot visit the factory in person, you can also search for factories through media, such as their official website, social media videos , Alibaba, and customer reviews, to understand the quality of a factory.

- Print quality : Does it support Pantone spot color printing to ensure that the colors are consistent with the renderings, without color deviation or inaccurate patterns? Are the edges of the printed patterns clear and free from smudging?

- Craftsmanship and texture : Whether the edges of hot stamping and silver stamping are neat and free of burrs, whether the UV spot varnishing areas are precise, and whether the embossed and relief patterns are three-dimensional and uniform. These details are the core competitiveness of high-end brand paper bags.

- Process stability : Are the die-cut bag openings and bottoms flat? Is the glue applied to the bags even, without any overflow or peeling? Is the defect rate in mass production too high?

IV. Rope Styles

The carrying handle is an integral part of the paper bag and is key to enhancing the customer experience. You can focus on the following points:

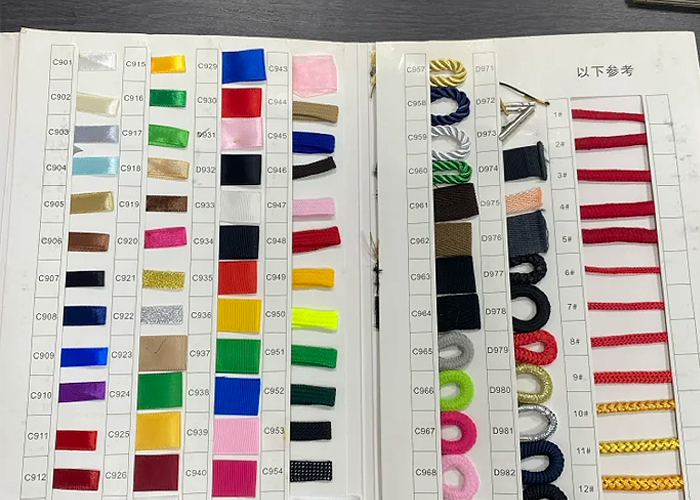

- A variety of styles are available: for example, cotton rope is soft to the touch and suitable for affordable luxury gift bags; paper rope is completely biodegradable and complies with new environmental regulations , making it suitable for eco-friendly brands; nylon rope is strong and suitable for shopping bags for large items; and ribbons have a natural sheen and a silky texture , making them suitable for luxury paper bags.

- Color and fixing process : Can the rope color be customized according to your needs? Is the rope fixing method secure? For ordinary products, choose the threaded rope or adhesive rope method. For heavy products, choose the glue-applied reinforcement or metal buckle fixing to prevent the rope from falling off when carried by hand.

- Size : The size of the rope will also affect the effect of the paper bag, depending on the size of the paper bag and the load-bearing requirements. Generally, the rope length is 32mm-40mm, but it can be adjusted according to the size of the paper bag.

V. Case Studies

Below are JS Packaging’s latest New Year gift bag designs. You can refer to the materials, craftsmanship, and rope combinations to get a more intuitive feel for our packaging quality.

- Gold-stamped drawstring gift bag: 250g white cardstock with matte finish, offering a particularly comfortable feel and a sense of tranquility and elegance. This New Year’s gift bag, customized by a European and American brand, features a four-color printing process with a gold-stamped logo, exuding high-end sophistication. The perforated five-strand drawstring matches the bag’s color, creating a cohesive look. The matte finish provides a particularly comfortable feel, contributing to a serene and elegant ambiance.

- ed Card Gift Bag : This new clothing gift bag features a metallic sheen from the red cardstock material , making it eye-catching and a popular choice for many high-end brands. The hot-stamped black logo highlights the brand and reinforces its image for customers. The soft cotton rope material perfectly matches the style of the clothing brand.

- Glossy Gift Bag : 250g white cardstock + glossy film , smooth surface, delicate touch , reflects ambient light , enhancing the packaging quality; the ribbon handle is also printed with the brand slogan, the adhesive rope process is sturdy and durable, full of details, allowing customers to feel the brand’s care and quality.

VI. Factory direct supply

Middlemen are a significant factor influencing prices. Working directly with the factory eliminates unnecessary markups, allowing you to obtain high-quality paper bags at a reasonable cost. JS Packaging is such a factory. We have QC inspection capabilities, and every batch of goods undergoes three rounds of full inspection before shipment to prevent defective products from leaving the factory. We have years of experience serving the global market. Our minimum order quantity (MOQ) is 1000 pieces , and large orders can enjoy sample fee deductions. You can visit our factory in person or via video tour, and our multiple social media accounts will give you a clear understanding of our capabilities.

If you’re ready to customize paper bags, JS Packaging is happy to assist. Send us your design or specific requirements, and we’ll provide you with a detailed quote and renderings within 24 hours. We also offer sample services—simply provide your address, and we’ll arrange shipping immediately.