As we know, when you custom your packaging, many ways of printing you can choose, if you don’t know that and your packaging consultant don’t give you suggestion, maybe your product of printing is not satisfy to you.And then every process has its own advantages and disadvantages, so that choose the right printing methods is very important.Js packaging factory will tell me how to choose and introduce different types of printing, let your packaging customized always is satisfied to you.

The following are 4 printing processes commonly used in packaging printing.

- Flexographic printing

Flexographic printing uses polyester or other flexible materials to make printing plates, which have good flexibility. Then it is installed on a drum to transfer ink to the relief plate through an anilox roller. When the printing material contacts the relief plate, the graphics are printed, which is very suitable for large-scale production. Flexographic printing has a wide range of uses. Because the printing plate is elastic, it can maintain good printing effects on various printing materials. In the packaging and printing industry, the corrugated box and paper box, paper bags usually use flexographic printing.

Advantages: it is cost-effective,the printing plate is low and save the production cost, and more fewer printing restrictions. It is popular in packaging printing because of the economical and efficient printing method.

Disadvantages: Flexographic printing is subject to technology and is not suitable for printing designs with complex colors. The color expression is relatively weak and cannot reproduce high-quality images.

- Offset printing

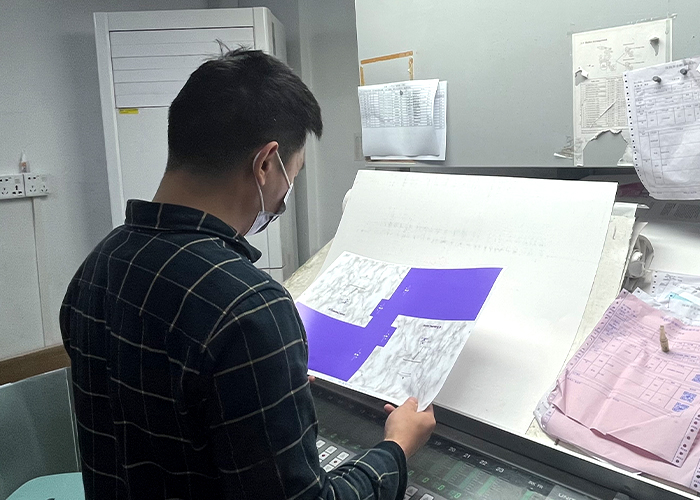

Offset printing is also called lithography. The first step from the printing plate to the rubber cloth cylinder in transfers the graphics , and then the material transfers the surface to the packaging box. Offset printing can prevent the water from to transfer the surface of the printing material together with the ink on the printing surface, and can accurately restore the image and text details. With offset printing, you can get perfect packaging and printing products. Customer’s packaging such as cosmetic boxes, e-commerce boxes, and food boxes are all offset printing works.

Advantages: The image quality printed by offset printing is high, and it can achieve very high resolution, and can complete the task of batch printing with high quality.

Disadvantages: Offset printing requires the surface of the printed material to be flat, the cost of plate making is high, and large-volume orders are required to obtain economic benefits. Large orders usually take longer to deliver.

- Screen printing

Screen printing is a hole printing technology that transfers ink to the surface of the printed material through the mesh of the screen. Screen printing does not require whether the surface of the printed material is flat, which means that it has a wide range of applications, and paper, fabric, glass and metal can be used as printing options.

Advantages: The plate making cost of screen printing is low, and a thicker ink layer can be printed, and three-dimensional graphics and text can be printed.

Disadvantages: Because the equipment is simple, it cannot print fine graphics, the production efficiency is low, and it is not suitable for large-scale printing work. Moreover, the printing surface is usually not very clean, and human errors are more likely to occur.

- Digital printing

Digital printing is to print electronic images directly onto the printing material, without the need for template tools, and saves many steps of traditional printing. Now the technology of digital printing is developing rapidly, and the printing quality is constantly improving. The printing quality of digital printing machines with advanced equipment is higher than that of flexographic printing. Of course, our Js Packaging can do this.

Advantages: Digital printing does not require plate making, can achieve fast printing, and is used for small-batch customization. It has a very large cost advantage for customized samples that need to be delivered quickly.

Disadvantages: Code printing ink cannot use metallic ink, and cannot provide coating options like lithographic printing. Moreover, if the number of prints is large, the cost will increase rapidly, which is not suitable for large-scale efficient production. When printing packaging boxes, please carefully consider the printing quantity, pattern design and cost. If you want high-quality and color-accurate packaging boxes, then offset printing is the most suitable. If you want to get samples faster, then digital printing is a good choice. Only by considering these three factors can you get cost-effective and high-quality printed packaging boxes. If you need more professional services, please contact js packaging.