The brand logo is the key factor that distinguishes the packaging from similar products, and the logo effects produced by different printing processes are completely different. Not only is the cost difference, but also directly affects the appearance of the packaging products. Js packaging factory will share the characteristics of different printing processes to help you choose the right logo printing process.

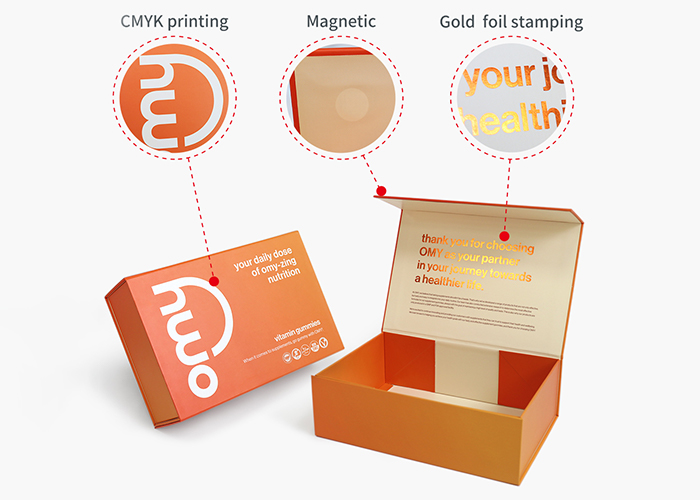

CMYK printing

CMYK printing is the four basic ink printing colors of Cyan, Magenta, Yellow, and Key. These four color inks can be mixed and modulated in different proportions to print a large number of colors. If your design or logo is brightly colored, CMYK printing can perfectly present the color effect you want. Usually this is an economical and efficient way to achieve high-quality printing, which can meet the customized needs of different companies for packaging logos. We owned advanced digital printing machines and can provide customized sample services. When customizing samples, digital printing has a lower cost and can change the sample design more efficiently, thereby reducing the additional sample production costs. Usually we can complete the proofing work within 3-5 days. After your confirmation, we choose offset printing (or flexographic printing) to complete higher quality printing products for you. For customers who require high color accuracy, we provide spot/pantone color printing services. Spot color printing can avoid color deviation problems that may occur during display and printing color matching on different monitors, and can ensure the consistency of the printed brand logo color and design color.

Hot stamping

Hot stamping is the most commonly used logo printing processing method. Except the classic gold hot stamping, there are colors will used, such as include silver, red, black, blue, purple, green, etc., which can choose according to your brand, which can make your brand more attractive. Hot/foil stamping used high temperature and high pressure to stick aluminum foil to the packaging brand logo position, which can make the logo more shine, make the packaging looks great. Hot stamping is very common in luxury gift box packaging, cosmetic packaging, jewelry packaging,skincare packaging and other brand packaging, which can catch your eye and reflect the brand packaging quality and charm. Hot stamping requires professional printing equipment to produce high-quality hot stamping. We use Heidelberg printing machines, and the hot stamping produced is stable and not afraid of scratches, and the effect lasts very long. Many ordinary processing plants will fall off quickly.

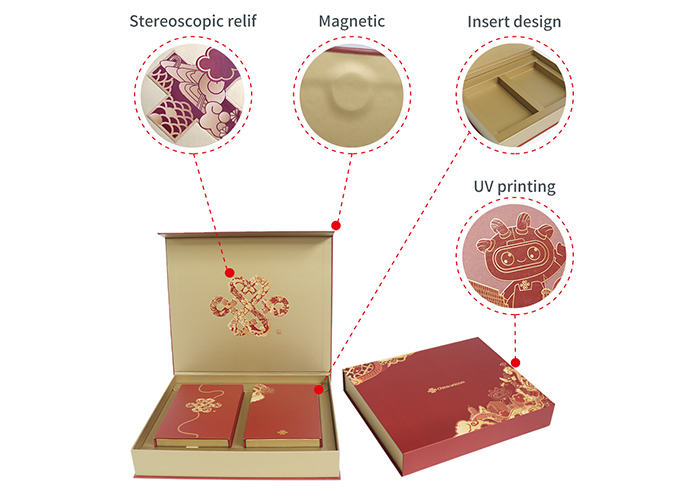

UV printing

UV is usually a local modification of the part that needs to be highlighted. UV materials are transparent inks that are cured with ultraviolet rays. After partial UV treatment, the logo or pattern will produce a bright glossy effect, which will be more vivid and three-dimensional compared to the surrounding patterns, and will make the brand logo more wear-resistant. This can help enhance the visual appeal, bring a three-dimensional tactile experience, and thus highlight the brand logo.

Embossing & Debossing

Embossing and debossing are completed with the help of customized mold pressing. This process can leave a very cool logo visual effect on the paper surface without using ink. Embossing is to make the pattern and logo raised by pressure, and the production of debossing is just the opposite. The pattern and logo will be pressed into the paper. Both can produce a three-dimensional effect on the flat paper surface and increase the sense of layering. This artistic effect will stand out in any project, giving your printed packaging a sense of luxury and helping to enhance the brand image. Paper that is too thin for both processes is not suitable. It is recommended to use thicker paper so that the three-dimensional effect produced is obvious, generally requiring more than 250G. Embossing is usually used together with hot stamping. The three-dimensional hot stamping brand logo will be more prominent. This is also a common processing method for luxury brands. At the same time, the three-dimensional hot stamping process is more complicated and requires high-precision and high-quality printing machines to achieve. Of course, Js packaging can easily produce it, and you can rest assured to hand over the project to us.

Texture

Texture through a mold with patterns, which can make the entire paper have regular textures or patterns, such as patterns, wood grains, cloth grains, leather grains, etc., or complex pattern designs. Texture and embossing are both completed by pressing. Embossing focuses on strengthening brand patterns and logos, while Texture focuses on changing the smooth surface of the packaging, bringing a unique touch and visual effect to the product packaging, and bringing higher brand added value, which is impossible for smooth paper.

The above printing surface finished processes can be combined with each other to create personalized product packaging. No matter what creative ideas you have, Js packaging can offer you one stop packaging solution service, and we will help you choose the right printing process to realize your creativity. Come and contact us to get your customized packaging!