CUSTOM BLACK CORRUGATED BOX

Product Specification

Usage: Apparel, garment, clothing

Box Type: Cardboard Rigid/Folding

Material:Paperboard,Cardboard, Colored Paperboard, Rigid Paperboard

Thickness: 1200gsm(2mm), 1500gsm(2.5mm), 1800gsm(3mm)

Printing:CMYK,Pantone Color, Screen Printing, UV printing, Foil Printing

Surface Finishing: Matt Lamination, Varnishing, Stamping, Embossing, Glossy Lamination, UV Coating, Gold Foil

Feature: Matt Lamination,Glossy Lamination,Glossy Oil Valish, Velvet Lamination, Anti-Scratch Lamination, Laser Lamination, Degradable Lamination

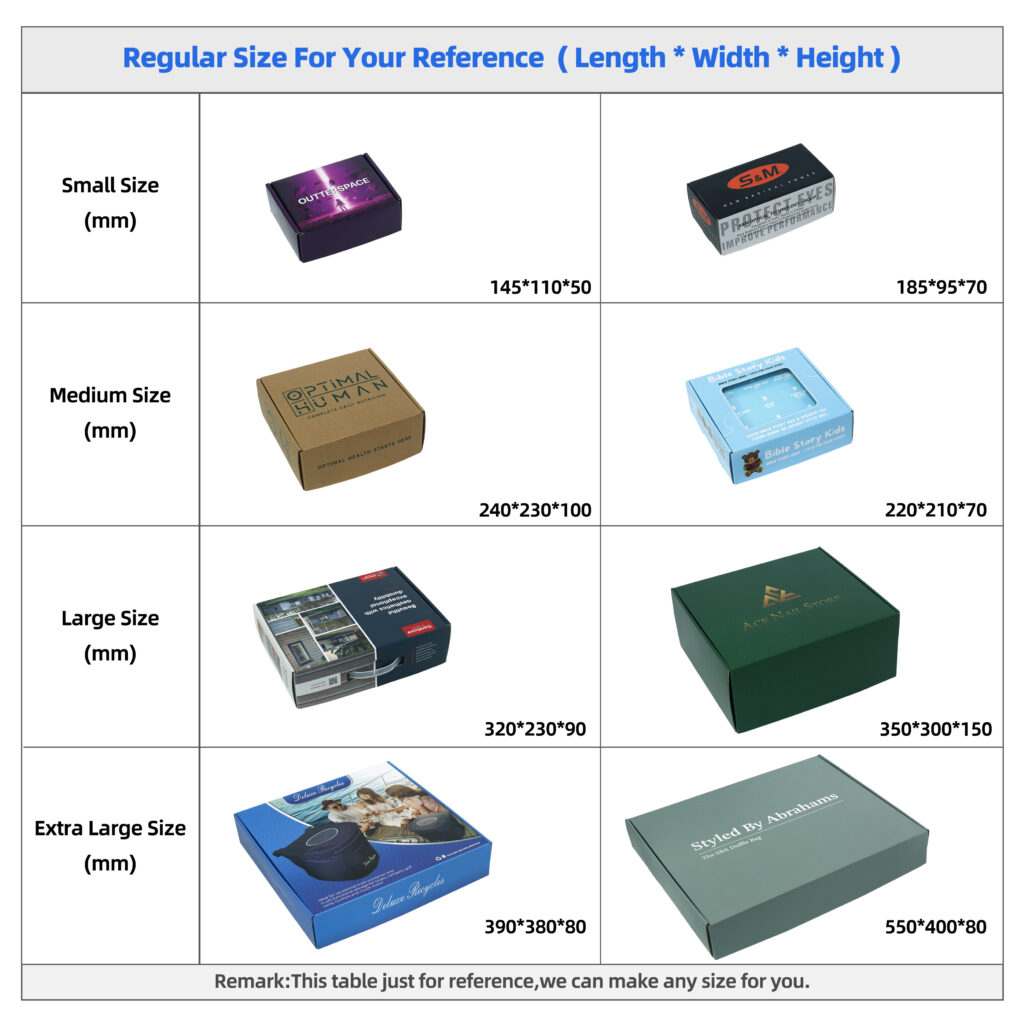

Logo,Design & Size: Customer’s Logo,Design And Size

Sample & Sample Time: Accept, 1-3Days

Production Time: 7-12Days

Shipping: Sea, Air, Express, Railway Shipping

Payment: T/T

Corrugated Paper Eco- Friendly

Corrugated material is like a trusty friend in the world of packaging. It’s made up of layers that give it strength and flexibility. But here’s the best part – it’s eco-friendly! You see, corrugated material is often made from recycled paper, which means it’s doing its part for our planet.

This eco-friendly material is not only strong enough to protect our precious items during shipping but also lightweight, making it easy to handle. And guess what? It can be easily recycled , reducing waste.

Craft Surface and Lamination

When it comes to custom packaging boxes, the choices of lamination and processes can really make a difference! Lamination is like giving your box an extra layer of protection and a nice finish. There are different types, like glossy lamination that makes your box shiny and catches the eye, or matte lamination for a more sophisticated and elegant look.

And then, we can talked about – hot stamping! Have you ever seen those shiny gold or silver accents on packaging boxes? That’s hot stamping! It can add a touch of luxury and make your box stand out. You can go for gold for a glamorous effect or silver for a modern and sleek look.

Another option is embossing. It creates raised patterns or designs on the box surface, giving it a tactile and unique feel.

The key is to think about your brand image and the message you want to convey. Choose the lamination and processes that best match your product and make it shine on the shelves. So you can choose your like, reliable supplier will help you.

Which One Insert You Like?

There are several options for you to choose inner. Firstly, there’s the setting option. It provides a stable and fixed position for your products, preventing them from moving around during transportation.

Then we have EVA. It’s a reliable choice that offers good support and protection.

Sponge is another great alternative. It’s soft and can cushion your items, especially delicate ones.

EPE foam is known for its excellent shock-absorbing properties, making it perfect for fragile goods.

The right inner support not only protects your items but also enhances the overall presentation of your packaging. So, take your time to select the one that meets your needs and makes your customers happy when they open the box! We can custom your needs, looking for your order.

About Delivery & Payment

Within 24 hours after confirm the details.

After we receive the relevant expenses,the samples will be ready and sent to you via express in 3-10 workdays.

Normally, it will take 7-10 days, about 10-15 days in peak season, mostly based on the quantities. Cargo will be packed in standard cartons and piled on pallets, or follow your requirements.Shrink wrapping is available as per request. Then the cargo will be delivered by sea or air.

Usually by T/T in advance. We can also support at least 30% of total amount paid in advance as down payment before mass production,and the rest should be paid before shipment or against copy of B/L.

About Services

Yes, customized sample will be charged according to your requirements, we also offer free sample for you to check

quality, but we do not cover the shipping cost.

1000pcs /design as start, smaller quantity negotiable.