With the growing popularity of eco-friendly consumption, paper gift boxes have become the mainstream choice for customized gift boxes across various industries. However, the selection of paper gift box materials is incredibly diverse, ranging from cardboard weight to face paper type. Making the wrong choice can not only lower the quality of the gift box but also increase production costs and transportation losses. As a factory with 27 years of experience in the packaging and printing industry, JS Packaging has served numerous luxury brands and corporate clients. Today, we’ll break down the selection techniques for cardboard and face paper to help you avoid customization pitfalls and choose gift box materials that match your brand positioning and usage scenario.

Common types of cardboard for gift boxes

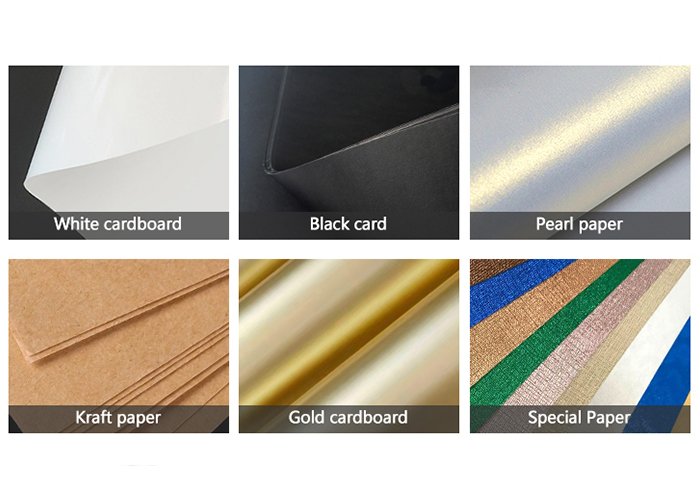

All paper gift boxes consist of two parts: a base cardboard and a face paper. The base cardboard determines the box’s rigidity, load-bearing capacity, and durability; the face paper directly affects the box’s visual appeal, printing quality, and brand image, and is also the carrier for processes such as hot stamping, UV coating, and embossing. Choosing the right combination of these two components is the core of gift box customization. Below is a basic introduction to cardboard :

Cardboard styles : Double-sided gray cardboard offers the best value, suitable for standard gift boxes where the face paper fully covers the cardboard and no exposed cardboard is needed; it’s the basic style for corporate customization. Single-sided white-gray cardboard, with one side white and the other gray, is suitable for gift boxes with partial exposed cardboard and minimalist designs, reducing the cost of face paper. Single-sided/double-sided black-gray cardboard has a sophisticated matte black texture, suitable for light luxury and high-end brand gift boxes; it looks excellent with gold foil stamping, enhancing the sense of luxury. Choose according to your specific needs.

Cardboard thickness : The basis weight range for gift box cardboard is 800g-2200g. Basis weight is directly related to thickness; the higher the basis weight, the thicker the cardboard and the stronger its load-bearing capacity. The mainstream gift box thicknesses are: 1000g (1.6mm), 1200g (2mm), 1500g (2.5mm), and 1800g (3mm). There’s no need to pursue excessively thick cardboard, nor should you choose excessively thin cardboard. Excessively thin cardboard is easily deformed and has poor protective properties; excessively thick cardboard will increase the weight of the gift box, increasing transportation and production costs. The above four mainstream thicknesses can meet the protection needs of over 90% of gift boxes; choose flexibly according to the gift box size and product weight.

II. Gift Box Facial Tissue

The face paper is the “face value” of a gift box, directly determining the printing effect, craftsmanship display, and brand visual expression. Different face papers vary greatly in smoothness, gloss, and material characteristics, and are suited to different printing processes and brand styles. At the same time, the choice of face paper weight is also crucial, as it is the foundation for ensuring the quality of the printing process.

Mainstream tissue paper categories for gift boxes:

- White cardstock : With its smoothness, stiffness, and gloss, it can accurately reproduce high-definition images and vibrant colors, making it a versatile choice for custom gift boxes. It is compatible with all surface treatments such as hot stamping, UV coating, embossing, and lamination, perfectly showcasing the design details of the gift box. White cardstock is also frequently used to make paper bags, achieving a unified style between the gift box and the bag.

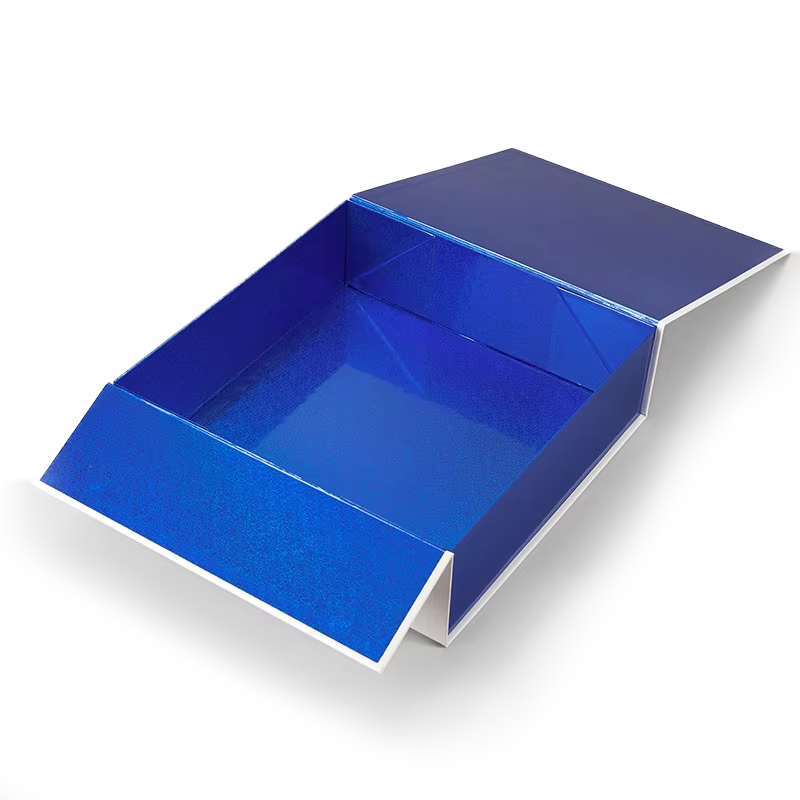

- Black cardstock : With its high smoothness and flatness, and a subtly mysterious matte texture, it’s the perfect choice for creating understated luxury and high-end gift boxes. When paired with gold foil stamping, the strong contrast between black and gold, black and white, or black and silver instantly elevates the gift box’s luxurious feel and brand image, making it suitable for minimalist, high-end brand positioning.

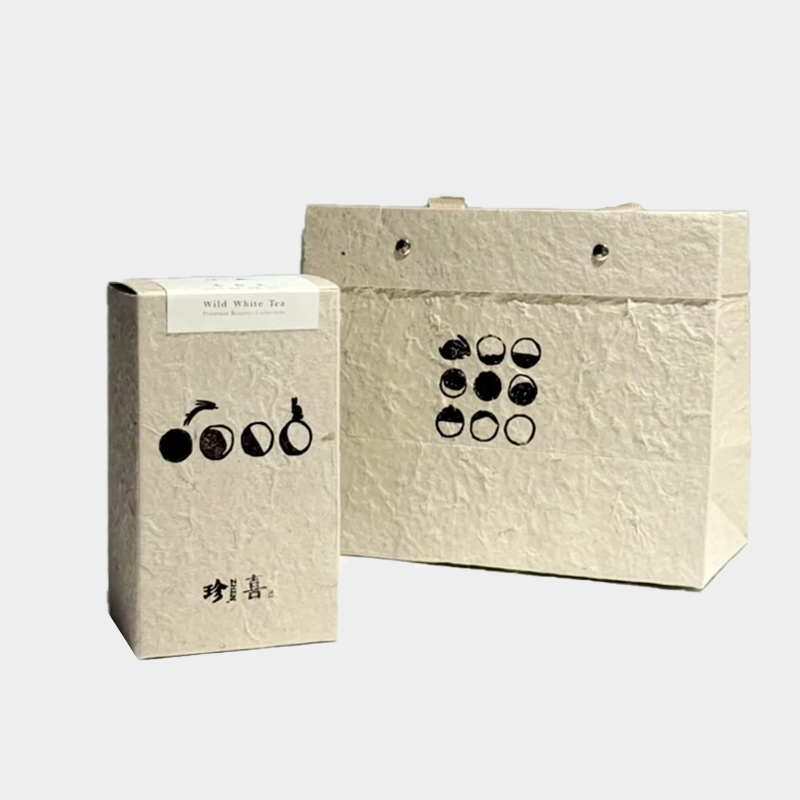

- Kraft paper : Made from natural wood fibers, it is biodegradable and 100% recyclable, aligning with the brand’s green and environmentally friendly philosophy. The material is flexible yet strong, wear-resistant, and tear-resistant, but its printability is relatively low, making it difficult to reproduce vibrant colors. It is suitable for gift boxes with a simple, rustic, and natural style .

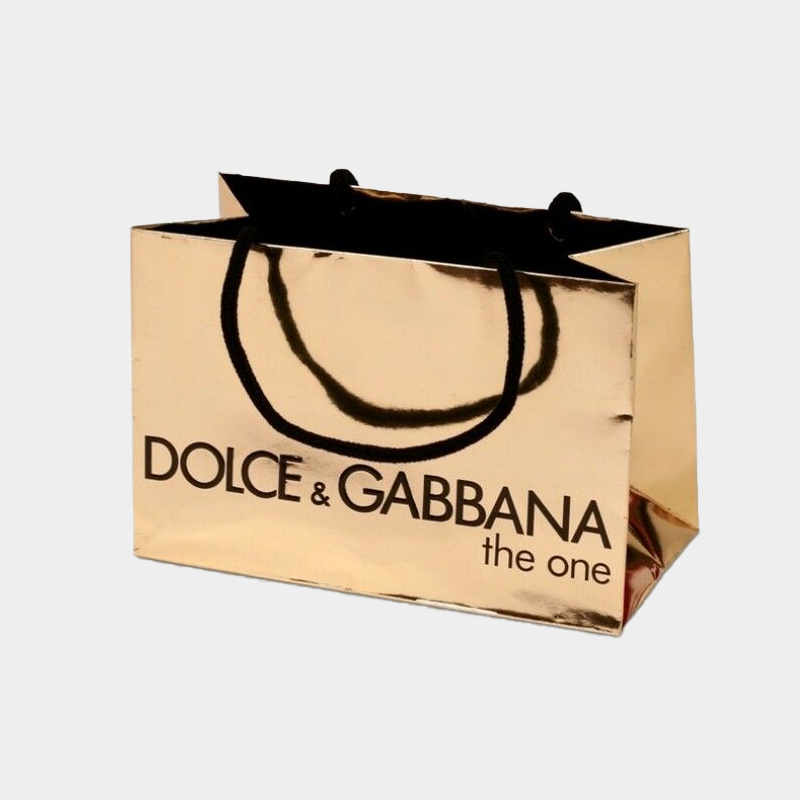

- Gold/silver cardstock : Its reflective surface with a metallic luster creates a strong visual impact, quickly enhancing the premium feel and recognizability of the gift box, giving it a luxurious and elegant quality. It’s a classic choice for luxury brands and high-end gift boxes, compatible with hot stamping and lamination processes, and suitable for limited-edition holidays and customized high-end gift boxes.

- Pearl paper : The core feature of pearl paper is its delicate pearl luster and warm, high-end texture, making it a standard for high-end skincare products, cosmetics, and luxury gift boxes .

- Specialty papers : such as tactile paper, holographic paper, and embossed paper, can meet the personalized needs of customized gift boxes, create a unique brand visual, and are suitable for niche, high-end gift box customization that focuses on differentiation.

Tips for choosing tissue weight

The grammage of the face paper directly affects the printing effect and the ability to withstand processes: low grammage face paper is prone to ink penetration and paper wrinkling, which not only affects the printing quality, but also cannot support processes such as hot stamping, embossing, and UV coating, and is prone to process peeling; excessive grammage will increase costs and may cause the face paper and paperboard to not adhere tightly, resulting in edge curling.

JS Packaging recommends 157g face paper , which is a cost-effective choice for customized gift boxes. It can meet the requirements of high-definition printing and mainstream surface treatments, and achieves a perfect balance between cost and quality, making it suitable for more than 90% of corporate gift box customization scenarios.

JS Packaging : Your Personal Packaging Consultant

When choosing materials and styles for gift boxes, more expensive isn’t always better. The best choice is the one that suits your needs. Combining brand positioning, product characteristics, usage scenarios, and budget will allow you to select high-quality, aesthetically pleasing customized gift boxes. JS Packaging , a professional packaging factory located in Shenzhen, China, provides one-stop customization services based on your brand needs, industry characteristics, and budget. From cardboard and linerboard to the final product, we professionally control the entire process, ensuring your customized gift boxes not only match your brand style but also balance practicality and cost-effectiveness. If you have any questions about gift box customization, please feel free to contact us. We will provide you with a personalized customization solution!