Printing is a core element of packaging production, directly determining the packaging’s visual appeal, texture, and brand expression. Choosing the right printing process can not only improve packaging quality but also enhance brand recognition and save on packaging costs . Today, JS Packaging will introduce five practical printing processes, analyzing their characteristics, applicable scenarios, and core advantages to help you select the most cost-effective packaging solution.

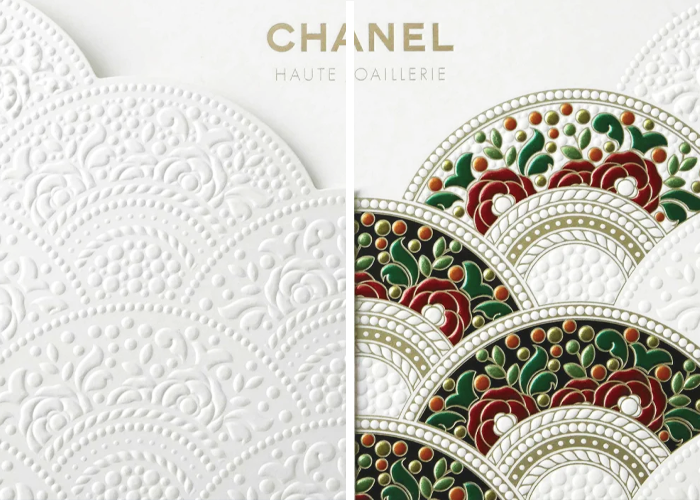

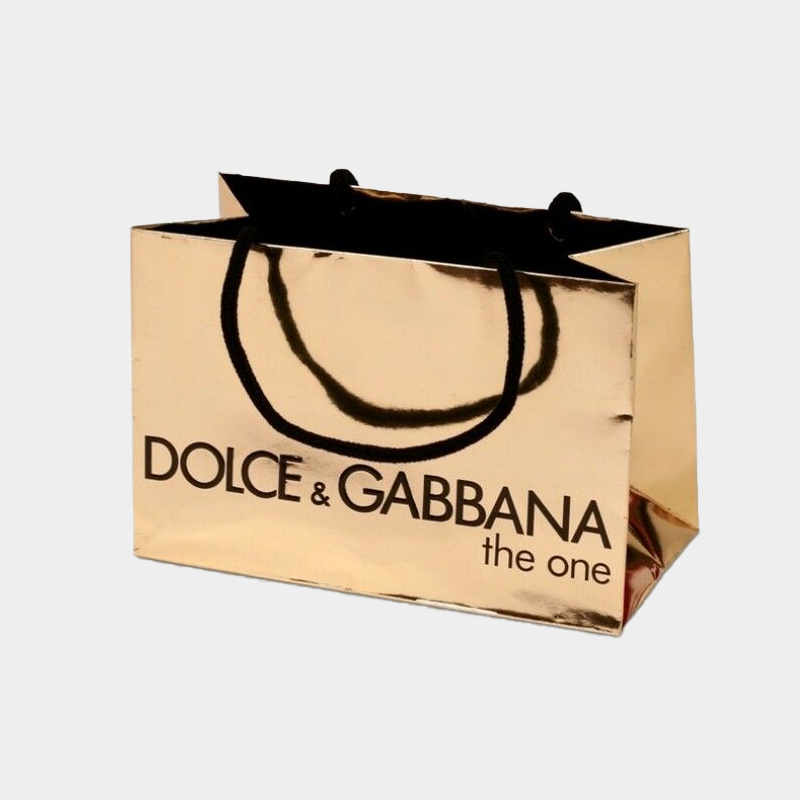

Gold foil stamping

Process Description: Utilizing hot-press transfer technology, metallic foil is hot-pressed onto the surface of printed materials to create a metallic pattern. Key Advantages: Strong metallic luster, slightly raised texture, high wear resistance, and resistance to oxidation, enhancing the product’s perceived quality. Commonly used on gift box surfaces, brand logos, and paper bag surfaces. It appears luxurious on dark-colored gift boxes and elegant and sophisticated on light-colored gift boxes. A variety of colors are available to choose from, allowing you to match a color scheme that suits your brand’s image.

Suitable for: cosmetic packaging, men’s gift boxes, clothing packaging, luxury goods packaging boxes, jewelry gift boxes, holiday gift boxes, etc.

UV printing

Process Description: UV varnish is applied to the surface of the printed material and instantly cured by ultraviolet light, forming a transparent coating. It boasts high gloss, a strong three-dimensional effect, and is wear- and scratch-resistant, accurately highlighting key design elements. This process is sophisticated and vibrant, suitable for fashion and trendy brands; environmentally conscious brands can also opt for soy-based inks.

Suitable for packaging: smart wearable gift boxes, electronic gift boxes, trendy brand hard boxes, technology product packaging boxes, car accessories ; men’s product gift boxes, etc.

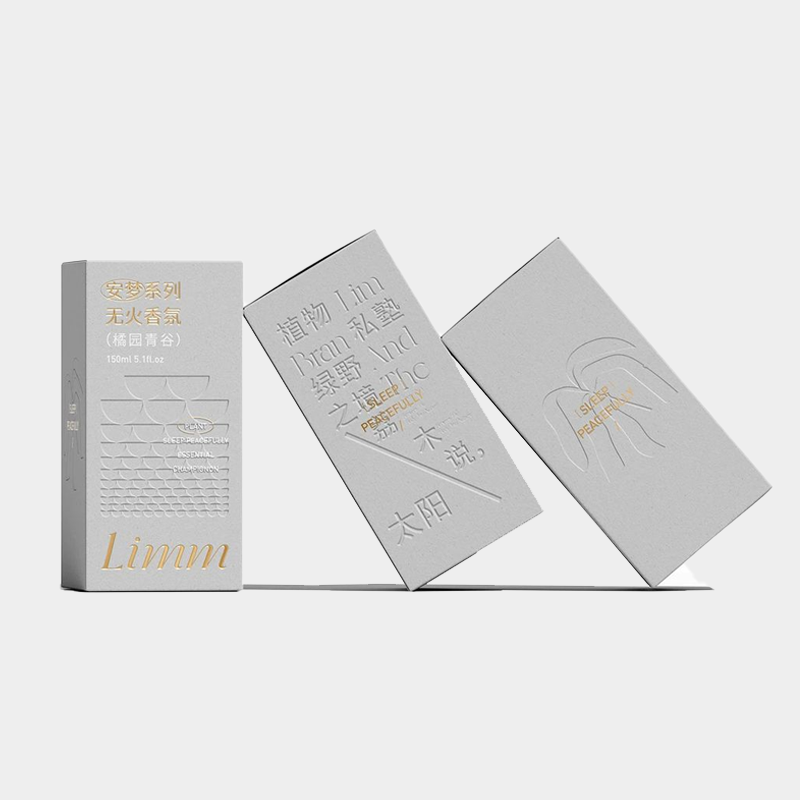

Protrusion

Process Description: This process utilizes barrier-free packaging design, allowing graphic and text areas to be raised while non-graphic and text areas are recessed. During printing, the raised areas are dipped in ink and pressed onto the packaging. Advantages include a distinct tactile feel, high color saturation, and clear, sharp lines. It is ideal for printing Braille, making it convenient for the elderly or those with disabilities, highlighting the brand’s humanitarianism and enhancing its social image.

Suitable packaging: Paralympic Games gift boxes, eco-friendly gift boxes, niche brand packaging, luxury brand packaging boxes, smart product gift boxes, senior citizen product gift boxes, etc.

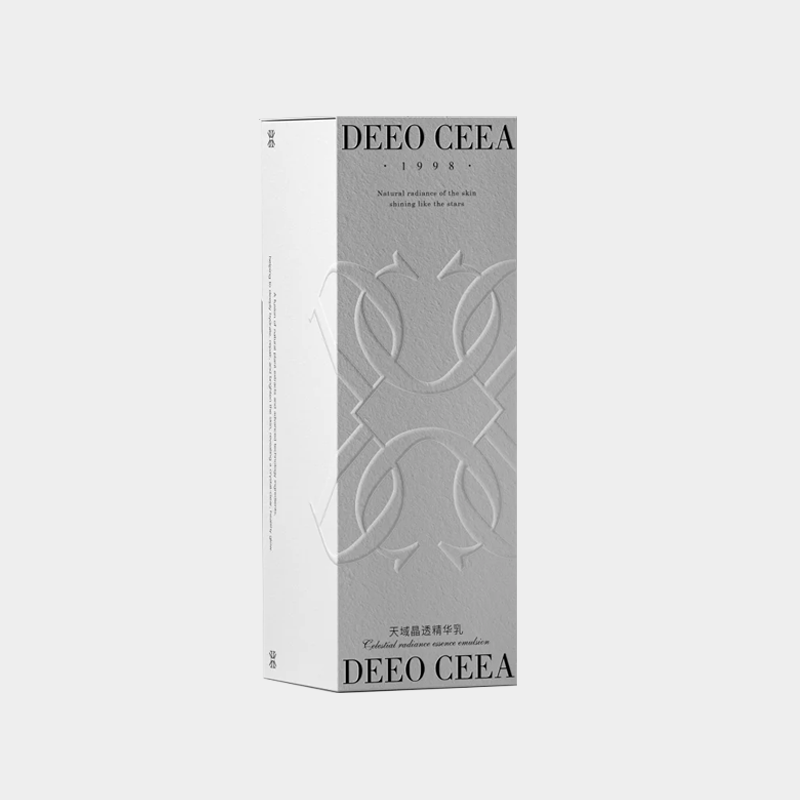

Embossed

Process Description: Using a mold with raised textures, a three-dimensional texture is created on the surface of the printed material under pressure, eliminating the need for ink. Core Advantages: Purely physical printing, environmentally friendly and odorless, offering a rich tactile experience and visual depth. Suitable for understated and eco-friendly brands, this process enriches the tactile and visual layers of packaging, enhancing its premium feel and allowing brands to upgrade their packaging at minimal cost.

Suitable packaging: eco-friendly gift boxes, specialty paper packaging, handmade gift boxes, beauty and skincare gift boxes, holiday gift boxes, etc.

Coating

Under heat and pressure . Different textures, such as glossy and matte lamination , are available to protect the printed surface and are environmentally friendly and odorless. The lamination layer is waterproof, scratch-resistant , and wear-resistant, effectively preventing fading and ink loss of the printed pattern. Glossy lamination enhances the packaging’s shine, while matte lamination creates a sophisticated matte texture, providing a dual upgrade in both visual appeal and tactile feel. This process strengthens the packaging’s protective performance and visual appeal, enhancing its overall sophistication.

Suitable for: general gift boxes, e-commerce gift boxes, beauty and skincare gift boxes, cultural and creative paper product packaging, holiday gift boxes, etc.

Customized packaging, choose JS Packaging

The five practical printing techniques mentioned above offer diverse and precise options for customized gift boxes, covering visual presentation, tactile experience, and cost control. They perfectly match the customization needs of different brand identities and product positioning. JS Packaging has deep expertise in the customized packaging field, possessing mature printing technology implementation capabilities and a professional customization service team. We can tailor a high-performance, cost-effective gift box customization solution for you based on your brand characteristics, product attributes, and budget. For customized gift boxes, please contact JS Packaging !