JSPackaging One-Stop Solution: From Design to Delivery

In today’s competitive market, custom packaging is not just about protection—it’s a key driver of brand value and customer experience. Whether you’re in the skincare, beauty device, perfume, apparel, or gift industry, having tailored, well-crafted packaging helps you stand out and elevate product perception.

At JSPackaging, we offer an end-to-end custom packaging solution—from structural design to prototyping, production, optional product kitting, secure packing, and international shipping. This guide walks you through each step of our packaging process from a client perspective.

Step 1: Packaging Design – Structural & Visual Integration

We offer two design approaches based on your needs:

Client-provided design files:

We’ll review print sizes, CMYK color, pantone color, or craftmanship to check technical specifications, and advise on sampling.

Design by JSPackaging:

Share your product size, logo file and printing color, use case, and branding—we’ll provide structure design and layout proposals that meet both aesthetic and functional requirements.

We specialize in custom box types such as magnetic folding boxes, rigid lid-and-base boxes, drawer boxes, mailer boxes, and multi-layer or irregular-shaped boxes. Inner support options include EVA, foam, paper inserts, plastic blisters, sponge,and molded pulp.

Step 2: Sample Development – Before Production

Before mass production, we strongly recommend making physical samples for evaluation and testing:

Lead Time:

- 3–5 business days

Quality Checks:

- Load-bearing, durability, structure, and print tests

Approval Methods:

- Remote photo/video approval or global shipping of physical samples

Shipping Time:

- 3–7 days depending on destination (via DHL/UPS/FedEx)

Samples ensure everything from structure to finish matches your expectations and can also be used for photography, presentations, or internal reviews.

Step 3: Bulk Production – Controlled and Flexible

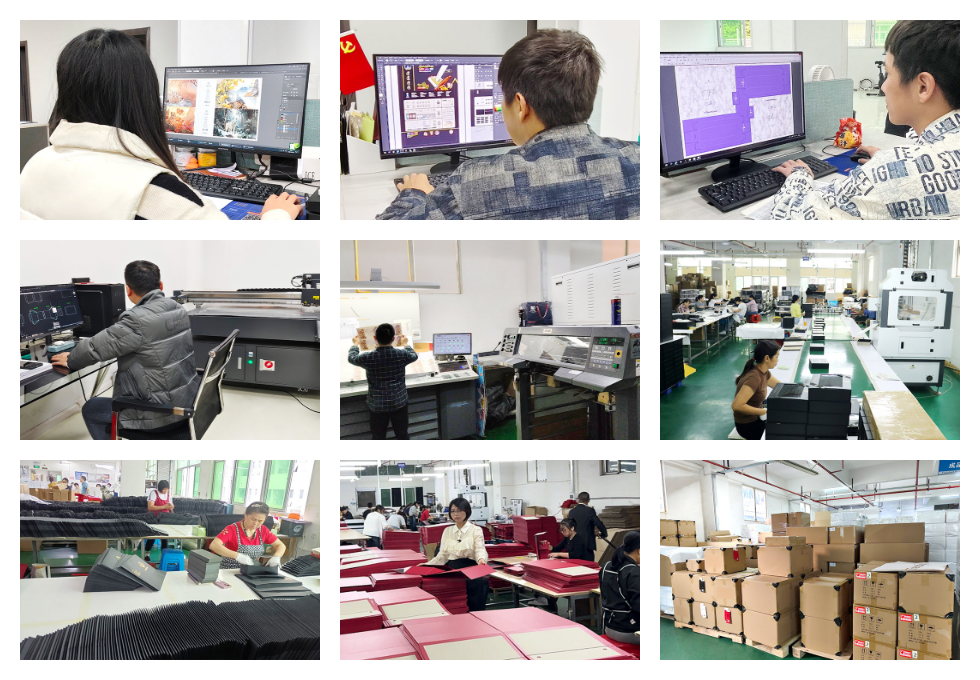

After your sample is approved, we move to full-scale production in our in-house factory to ensure tight quality and schedule control.

Color Proofing:

Pantone/CYMK accuracy matching before full print

Production Process:

Printing → Surface finish → Die-cutting → Assembly → QC

QC Management:

Multi-stage inspections to catch color, structure, or assembly issues early

Lead Time:

10–15 business days for standard orders; 5–10 days for urgent orders

Flexible Scheduling:

We accommodate partial deliveries or phased production as needed

Step 4: Value-Added Kitting – Product + Packaging Assembly

Need your product assembled inside the box before shipping? We offer assemble services:

Services:

Insert your product into packaging, place inner trays, apply stickers, add manuals, etc.

Best for:

Gift sets, influencer kits, e-commerce bundles, holiday packaging

Quality Assurance:

Each piece is double-checked to ensure consistent assembly

This service is ideal for brands shipping directly to distribution centers, end-customers, or online platforms.

We follow export standards and can adjust packaging per your specifications.

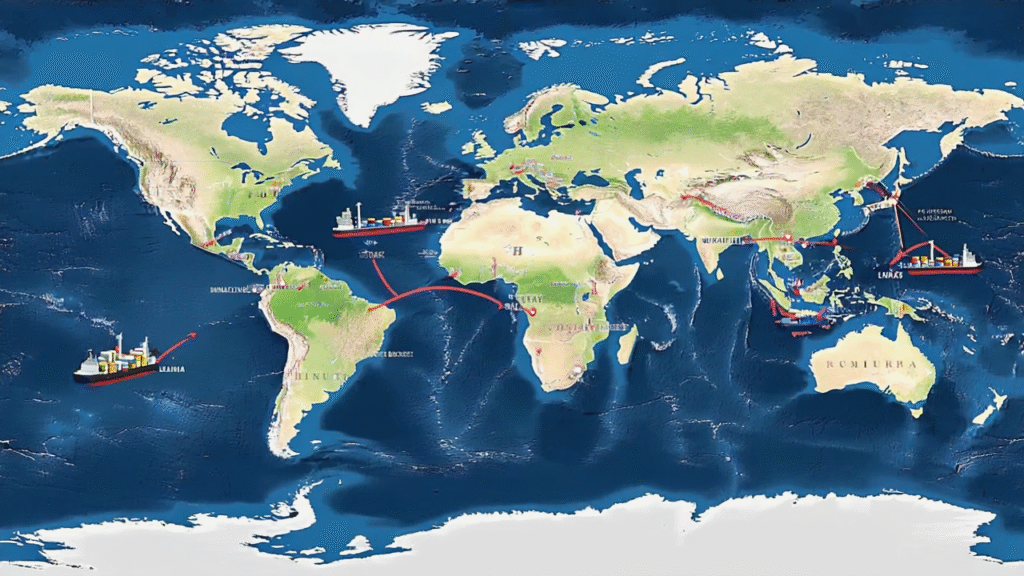

Courier:

DHL, UPS, FedEx (for samples or small batches)

Air Freight:

5–10 days transit

Ocean Freight:

Best for bulk, cost-effective shipments(DDP,CIF,FOB etc.)

Rail & Trucking:

For landlocked or inland countries

We help prepare all required export documents: commercial invoice, packing list, certificate of origin, and customs declarations.

Why Choose JSPackaging?

We’re more than just a packaging manufacturer—we’re your brand’s packaging partner. Here’s what makes us different:

🧩 All-in-one Service:

From creative to production, kitting to shipping

⚡ Fast Turnaround:

24/7 customer service available to respond anytime

🏭 Source Packaging Factory:

Reliable, consistent quality

🌍 International Logistics Expertise:

Smooth global delivery

🌱 Sustainability First:

Support FSC paper, recyclable & plastic-free materials